TECH4EFFECT presents at European Biomass Conference & Exhibition

TECH4EFFECT Co-ordinator and Head of Research of Forest and Forest Resources from the Norwegian Institute of Bioeconomy Research (NIBIO), Rasmus Astrup, recently presented how forest data and knowledge-based management could contribute to sustainable forestry at a sideline event of the digital 29th European Biomass Conference and Exhibition.

Astrup joined fellow scientists from the European Forest Institute, the Natural Resources Institute of Finland, LUKE, the Polytechnic University of Valencia and CREAF at a Speakers’ Corner event to discuss “Forest management in climate transition: good practices from applied experiences”. The event was organised by LIFE Resilient Forests under the chair of the European Biomass Industry Association.

He introduced the TECH4EFFECT project by stating that the forest sector needs to strive for greater efficiency continuously and systematically in production and environmental performance.

To anchor the topic of forest digitalization, he noted that between 1955 and 2005 there was a tremendous increase in forest machine efficiency when the sector witnessed unprecedented mechanisation and digitalization during that time.

“However, currently, a lot of technologies have reached saturation point, and it is my opinion that the next leap in efficiency will come from data driven decisions to improve production efficiency and environmental performance,” he said.

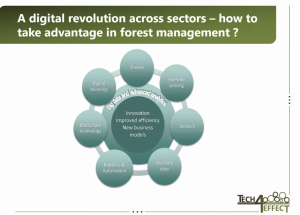

A digital revolution in forestry

This vision implies that the sector implements the possibilities for efficiency gains in incremental machine improvements and fully embraces the inherent possibilities within the ongoing digital revolution.

He said that currently there were many ways which were being used in forest management concerning the collection and recording of data using drones, sensors, remote sensing, digital twins, blockchain technology, data and even robotics.

Narrative key to data use

The key is to use these tools to create a narrative using big data for forest management, which could create innovative, new business models, capture further efficiency gains and even achieve increased profitability.

For example, digital tools can monitor the driving distance of the harvesting machine to the tree and the rolling resistance of wheels can be recorded to reduce environmental impacts to avert root shearing or wheel rutting.

Turning to silvicultural management, he said that precision forestry can identify diseases such as root rot in highlighting where a re-generation of the stand needs to take place, and even to establish which species could be re-planted according to the evidence collected through data.

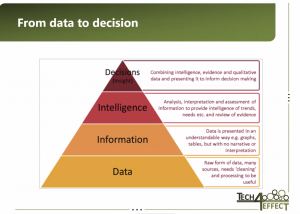

From data to decision

Turning to one of the project’s key results SILVISMART in collecting data from forest machines, he said that data was only useful if it could be converted into some form that was understandable, in that it gives a narrative, or a defined purpose for the end-users.

Any collected data would need to be analysed in the context of industry norms or trends, which then can be used for decision making, or business intelligence.

“Machine data is still highly underutilized for improving forest management, as well as in data sharing between different machines.

In terms of sharing data in SILVISMART, there would be strict controls as to who would have access to the information and how the information would be shared between forest actors.

This would be relevant especially when it came to any possible benchmarking of operations in assessing which operation was efficient and which was not as efficient, or even unsuccessful,” he said.

“Some forest actors may not want to share that with all parties. The real challenge now is convincing people to use these tools. This is a challenge because increased digitalization confronts the way we work, it deals with core concepts like willingness to share data, and even the awareness of knowing how digital tools can improve the management of our forests.”